Description

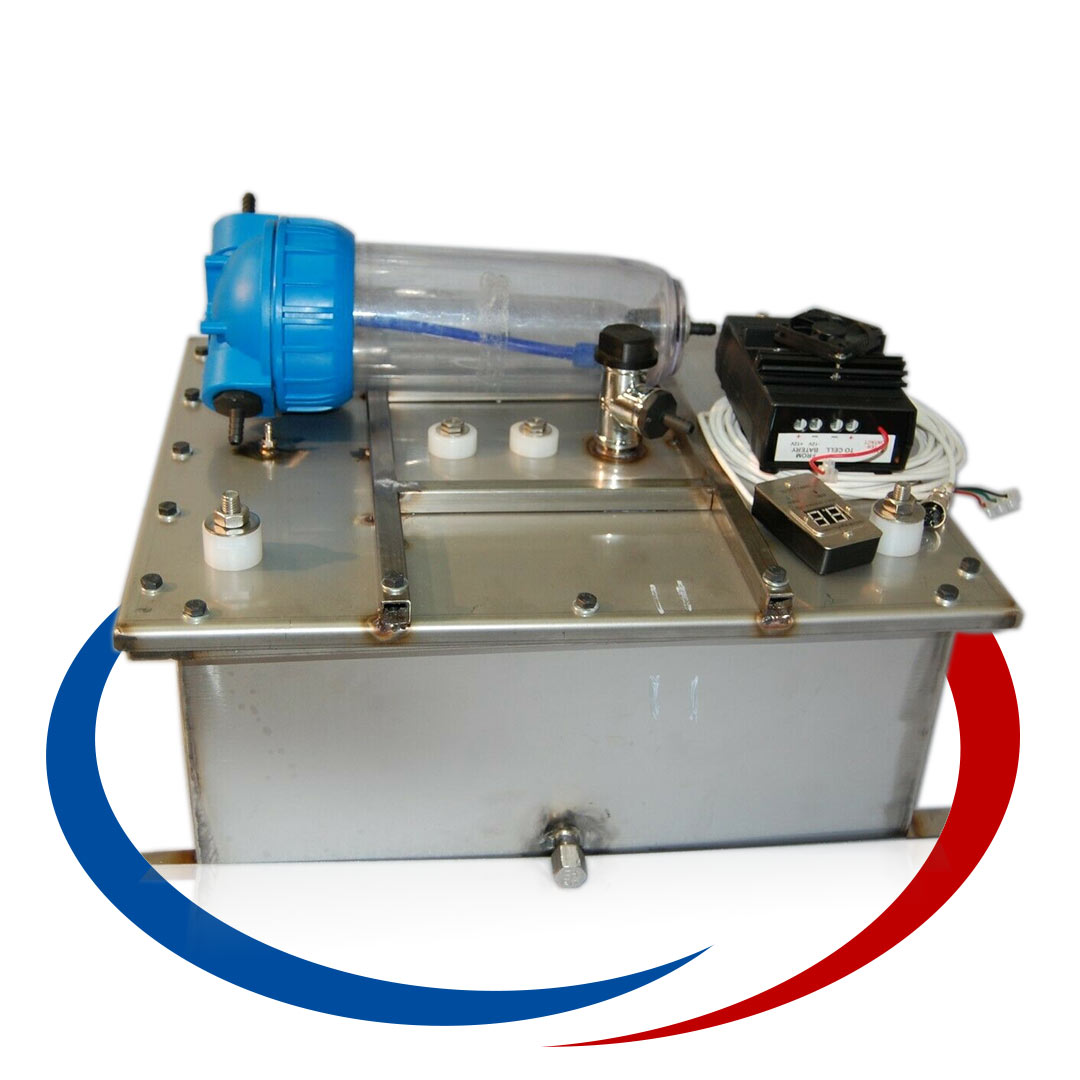

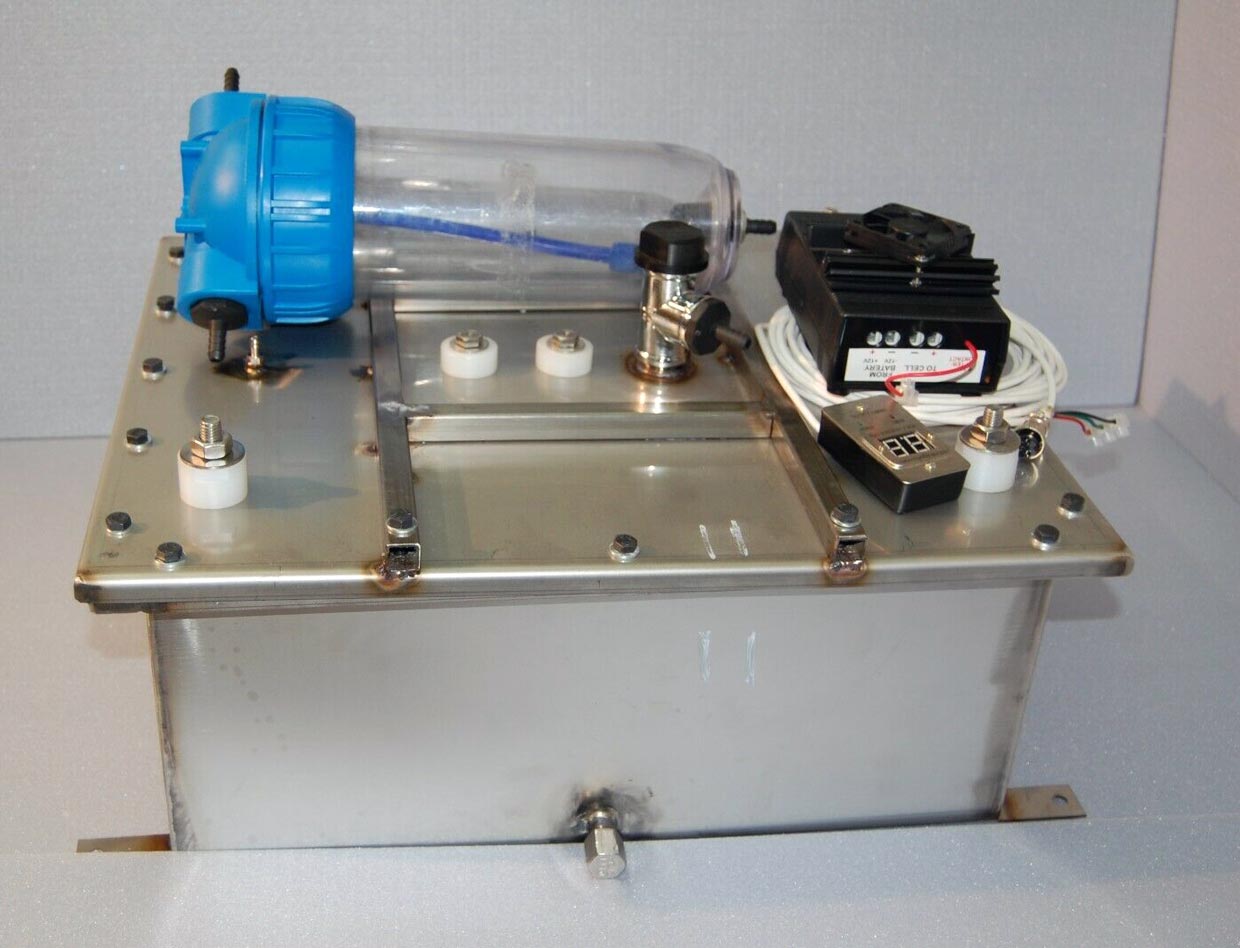

Multi-purpose Brawn’s Gas Generator HHOFrance-B2460

HHO cell HHOFrance-cell/2460

1. Operating voltage – 20-29 V

2. Load current – 3 to 60 А

3. Operation temperature – 15 to +50 degrees

4. Level gauge current consumption: – <10 mA

5. Electrolyte concentration (KOH) – 10 – 14%

6. Productivity – up to 8 l/min of Brawn’s gas.

7. Overall dimensions (mm): H=270, L=540 , W=420

8. Material

8.1.Casing – Steel 304

8.2. Electrodes – Steel 316L

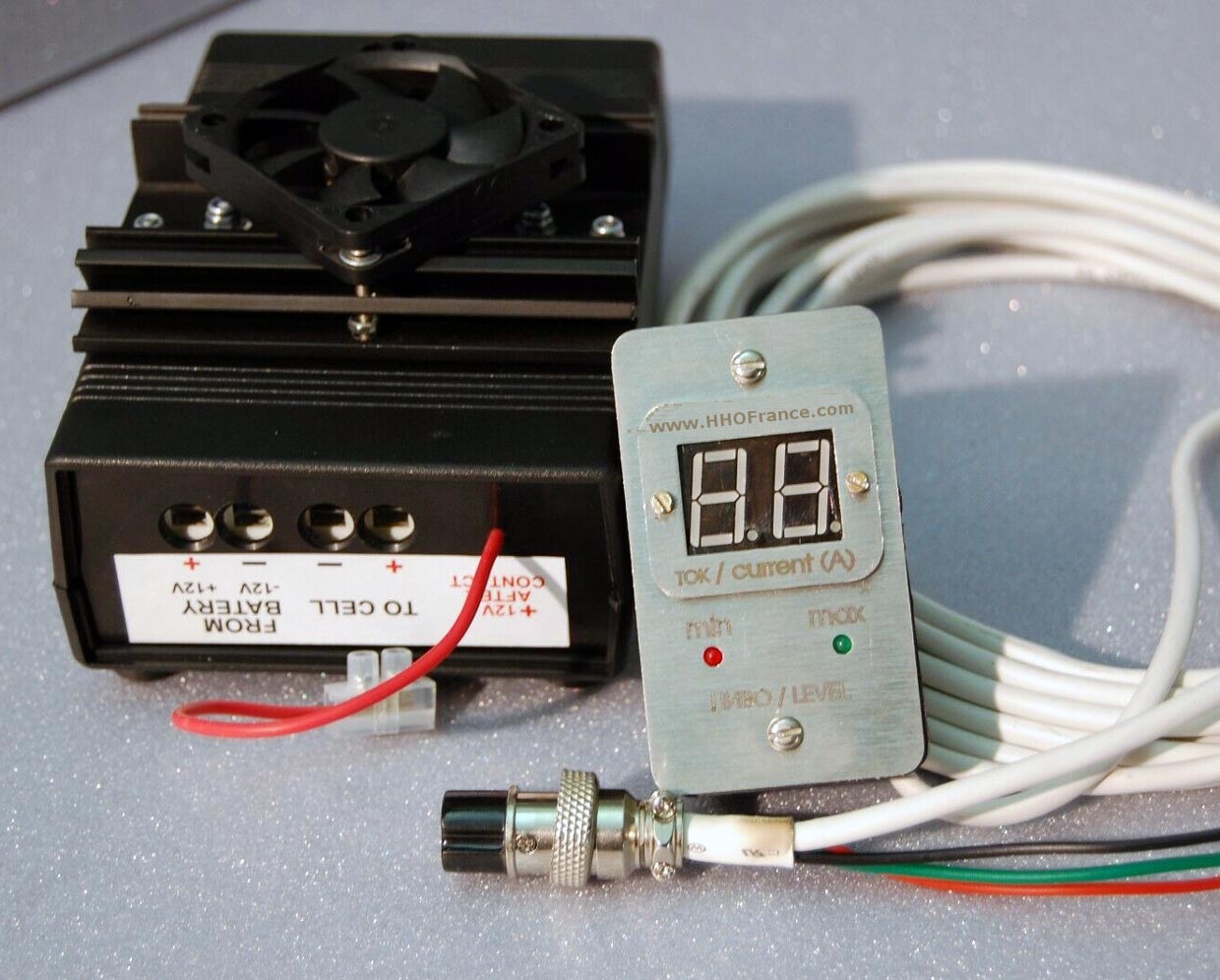

PWM / Process Controller PC12 for ННО – generator

1. Operating voltage 13/28 V

2. Working frequency – 1-3 kHz

3. Output current – <30А

4. Operation temperature – -15 to 80 degree Celsius

5. Adjusting method – Pulse Width Modulation

6. Casing material – polystyrene

7. Dimensions (mm) – L=95,4, H=43,2, W=84

FULL AUTO Plug-n-Play PWM HHO CONTROLLER FOR HHO GENERATORS WITH INDICATION MODULE – dynamic adjustment, automatic operation.

For the first time in the world, a fully automatic Plug-n-Play HHO PWM controller for Hydrogen Generator.

Connect the HHO controller to a + 12V power supply and GND and to the hydrogen cell, supply a control plus 12V after a contact and it automatically adjusts the current in HHO cell.

– New software for fully automatic operation of the HHO Hydrogen Generator without the need for additional sensor installation or sensor signals from vehicle sensors.

– Automatic reading of the pulses generated by the alternator to determine the operating mode of the engine and its speed.

– Automatic start after the driver contacts the vehicle.

– Automatically monitor engine speed. The HHO controller monitors the impulses generated by the car’s alternator and understands the speed of the engine.

– When the engine is running idle, the HHO controller feeds 3 A to the hydrogen cell.

– When the vehicle’s speed increases above 1200, the HHO controller automatically increases the current to the cell, which increases the production gas – Brown’s gas to the required engine volume.

– After removing the engine throttle and running idle, the engine automatically reduces the current supplied to the hydrogen cell to reduce the load on the alternator and achieve maximum fuel economy.

– Adjust the maximum working current through 3A by jumping a jumper. Values 15A, 18A, 21A, 24A, 27A and 30A.

– Automatic voltage test in the car’s electrical system. At startup of charging voltage from the alternator to the accumulator and reaching the level above 13.2 V, the contactor is switched on.

– When the vehicle’s electrical system is loaded due to many loads or alternator damage and the voltage falls below 12.8 V, the HHO controller disables the Brown Gas Generator.

– When the engine is switched off and the power generator is switched off, even if the ignition is not switched off, the HHO controller automatically turns off the Brown gas generator.

– Supply voltage 12V / 24V.

– Idle current 3A.

– Maximum working current 30A.

– Fixed maximum operating current regardless of heating and changes in hydrogen conductivity.

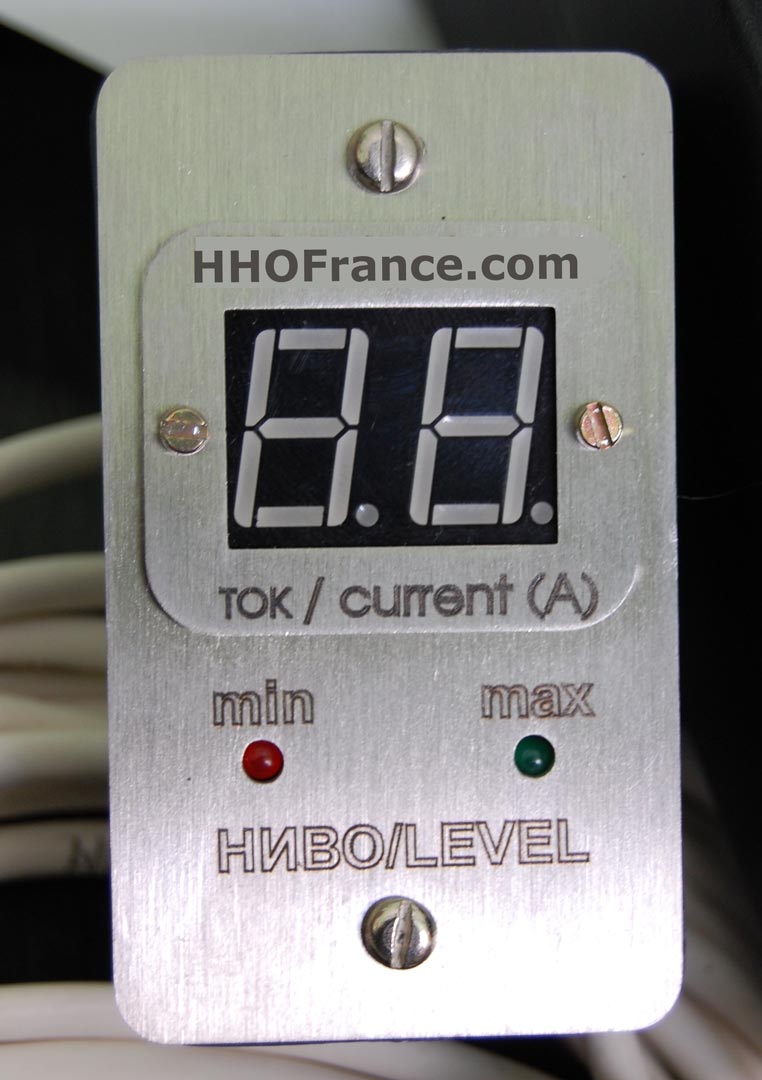

– An indication module showing the current current installed at the driver of the vehicle. The module also displays an electrolyte level in the cell with two green and red light indicators.

– A light indication indicating that the controller is prevented from reaching its set operating current due to problems in the operation of the hydrogen cell (a diluted or contaminated electrolyte) or a problem in the electrical connections.

– Button for automatic shutdown of automatic current regulation to the cell and operation of a fixed maximum value of the working current.

– No installation of a relay for turning on or off the hydrogen generator.

– In the event of a breakdown in the power components of the HHO controller, a circuit breaker is automatically switched on and burnt a fuse.

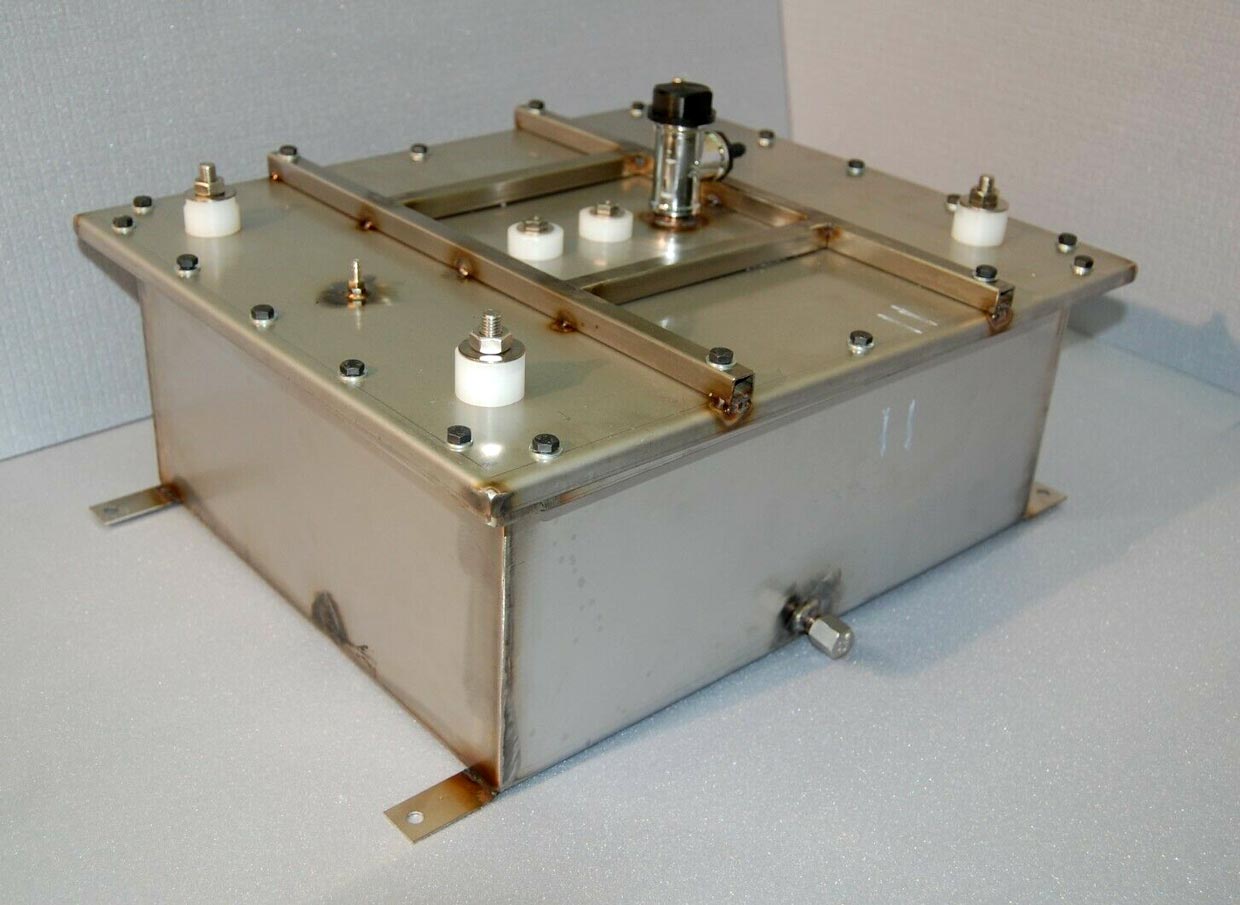

The Electrolyzer is a device wherein process of electrolyze is conducted via an electrochemical method and so it results in the generation of “Brown’s gas”. The electrolyzer casing is made from polypropylene – a material with very good features of resistance to temperature variations, vibrations, loads and aggressive chemical media. It has form of classic accumulator. It consists of casing, top cover, connecting pieces, valve and level gauge.

Electrodes are positioned inside the Electrolyzer. Electrolyze is performed with their assist. The electrodes are made from steel grade 316L. Electrode power supply is provided by means of stainless steel stud pins – А2 (grade 304). For assembly stainless steel washers and nuts are used. For better electric conductivity out of casing, the washers and nuts used for tightening cable shoes of Electrolyzer power supply unit, are made from plain steel – galvanized.

Stickers are used to indicate holes and connection pieces purposes. The power supply terminals are designated with + and – signs directly encrusted in casing plastic material. An information sticker about product name and manufacturer information and contacts is attached to the Electrolyzer. The text is in English.